Thanks for the offer Tom. Right now my big project is expanding my 18'x10 shed into a 18'x22' garage so I can fit the "C" into it then the fun starts!

Announcement

Collapse

No announcement yet.

SC Coupe Restoration

Collapse

X

-

I borrowed a shot by Mic from the Hershey meet. The lack of hood handle and the Bali blue color in the sunshine makes the hood show the contours and gaps fairly well. The owner of this car separated the lid skin from the frame as an early involvement in his car an I finished it. There was rust and it had been blown back and the cowl was a mess with a big curved crease the last guys filled with bondo. Still, it was blasted and repaired and as a nice Karmann touch, had the texture sprayed in to hide the myriad minor flaws not addressed but now covered up.

Comment

-

Cool thanks John for your measurements as well. Its rare that we all get the same thing! Enjoy your virgin hood and don't let it fall off the bench like I did.

I totally agree with you Justin about forum posts. For me it really encourages good work and I learn so much. For those of you who are just beginning the metal work phase, I hope that our posts aren't intimidating. My quality of work started out very shaky and progressed over almost 9 years. I will look for some photos of my first repairs and post them here for fun. Some of my early repairs have been re-worked as my skill improved. If you haven't posted your project on abcgt.com then do it, you will find it addicting and we are here to help if you need it.

Even though I should be at work. I couldn't focus until I trial fitted the hood.

As Bruce was saying in truth, more forceful "encouragement" is needed to match the contour. The photo below shows a tad too much curvature.

The right side is a little hung up due to the still open hem.

The point of this exercise was too ensure that it fits close enough to go ahead and epoxy primer/paint the inside. Then I will hammer the hems close to permanently marry these parts together. I may not spot weld until after the hoods fits perfectly. The spot welds will take away some of the flexibility.

I'm not going to try and bend the curvature with the hems open all over the place. Also I want the weather seal in place to do any fine tuning.

Regarding the seam sealer idea, I think its not a bad idea as anything would have been better than what the factory did. (untreated steel in an open cavity). My feeling is that epoxy primer and paint should be enough to protect these parts for a long time. My car will be garaged, so gone are the days of being left outside to rust.

Nice Bali blue car Bruce. My car is a Karmann, but didn't have the textured finish. No one is for sure if my hood was original....50/50 guess. Do you think its fairly safe to say all karmann coupe hoods had texture? Mine is 218094 64C. Thanks again for your expertise.

Today was a "fun" day, since my hood fits 100x better than it did when I bought this car 15 years ago and its not even close to done yet.

Cheers,

Tom

Comment

-

I am far from an expert but thinking about the seam sealer my first thought was it would not be able to breath so any moisture could/would get trapped from condensation. The way you guys are doing it is the best. Clean & epoxy prime will last longer than original & then throw in the fact that it will rarely ever see rain these will be good for longer than you can think.Mic

1959A coupe

Comment

-

Tom and Bruce,

This continues to be so interesting. I also liked your tile nibbler modification, really good thinking there. The gap of the frame to the lid made me take a few pics of my 356A front lid after I checked it. This lid is completely original apart from the spray I did. You can see a few areas I missed 25 years ago and my incorrect joining of the bonnet seal in the middle of the car instead of under the corner clip.

The fact I did not think about doing it under the clip amazes me. Of course when you read about doing it all makes sense. Bruces comments about getting the front lid to sit properly and with good gaps I have read twice now. My car had perfect gaps on the front lid and this changed somewhat when I first removed it. I did some metal removal and leading on the top area of the fender at the back Windscreen end over 35 years ago. I also then first replaced a seal. I had the lid then high on this side and wondered if the cutting had allowed the fender to drop. So next time in 89 I fitted another seal and found I needed to clamp tight one side hinge and torque slightly the other side down to correct it. This pulling and pushing has worked but the seal is more squashed in some areas than the others. Is this what you meant Bruce to get the perfect gap??

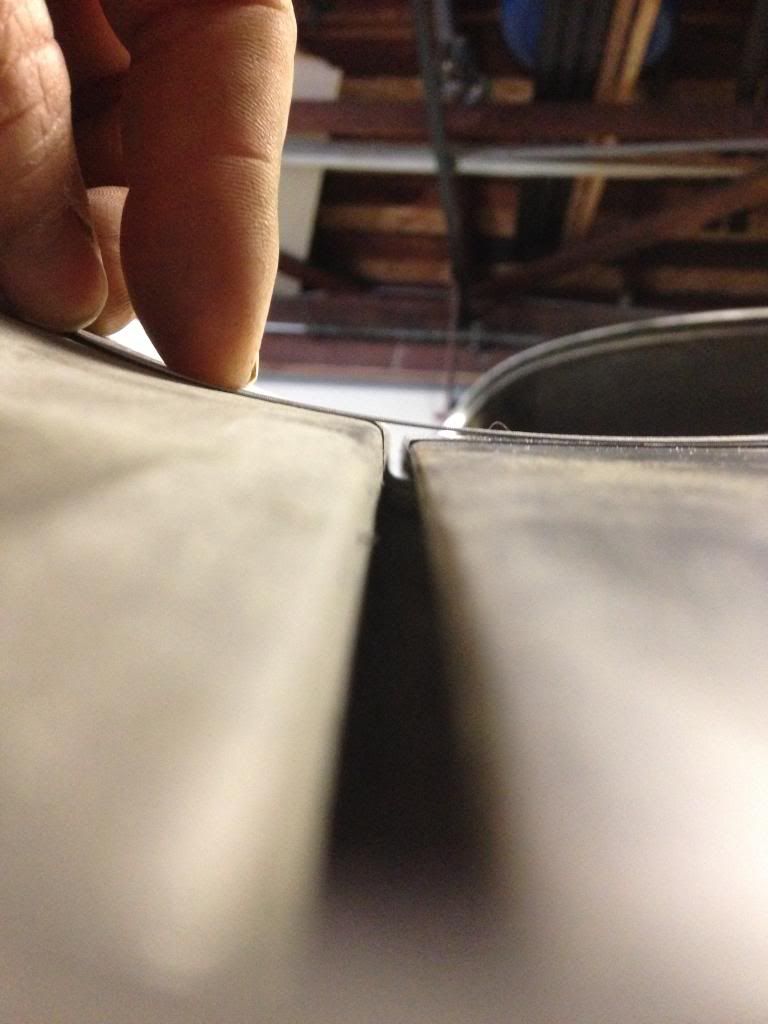

The photos should speak for themselves. But it does look like parts are held with a spot of weld. The maximum gap seems to be around 2 mm but I noticed small raised areas. The welding of the lip is really good so flat really nice. Maybe those with an A might find the pics of interest. I hope they show, the last ones I posted you have a box to 'click'each one to open it.

We will see!

Roy

Comment

-

Thanks Tom! Your last post rings so true, I've certainly made my share of mistakes like redoing my battery floor for a third time before it was right! Mistakes are just part of the process but posts like yours certainly will help to smooth out the journey! Your initial hood mock up looks very promising! I assume it was just laying in there unhinged, no seal and not latched of course since its not built, but you have a lot wiggle room to really perfect its final fitment. I also see in your second to last photo that your new hood is telling you exactly what needs to be corrected on the right side cowl corner. Congratulations and enjoy, this was a great day for you, and so nice to leave the garage feeling like your winning; Days like this do not come around too often which makes it all that much sweeter!

Mistakes are just part of the process but posts like yours certainly will help to smooth out the journey! Your initial hood mock up looks very promising! I assume it was just laying in there unhinged, no seal and not latched of course since its not built, but you have a lot wiggle room to really perfect its final fitment. I also see in your second to last photo that your new hood is telling you exactly what needs to be corrected on the right side cowl corner. Congratulations and enjoy, this was a great day for you, and so nice to leave the garage feeling like your winning; Days like this do not come around too often which makes it all that much sweeter!

Justin

Thanks Roy! BTW don't forget to hit "Insert" on each of your photo attachments so they will display large. Just did it for you. Justin Rio

Justin Rio

Comment

-

Well, maybe a few more would help.....Originally posted by foamcar" post=19064Well, I would dare say we now have the world's best data base of hood inner to outer gaps. Phil

Here is where a really good original lid helps align all the rest of the front body panels:

Here are other untouched originals and their variables:

Comment

-

Tom, truer words cannot be posted. I am [almost] embarrassed now when I get cars back after 35, 40 or more years for a 'freshening' and see my early 'crude' work. The work done by the old guys I hired is as good as it gets, so it's easy to tell who did what back then, but it's a constant learning process, no matter who, what or where.Originally posted by tperazzo" post=19026Some of my early repairs have been re-worked as my skill improved. Tom

When I was teaching elementary school art in the '60s (for one year...I learned to love it, but it was unabashedly to avoid the draft for 'Nam...and that didn't work)...I had little kids come to me and say "Mister Baker, Mister Baker...I messed up!" I'd calmly tell them that they had NOT "messed up," they just needed to practice more. Posted threads like this are the same.

For Roy; the various rubber seals available from different vendors often offer differing dimensions. A blessing and a curse but still only an inconvenience for a one-shot project to order all if one area needs that assist.

Pros can afford to buy all seals from all vendors and try each in all circumstances and have a shot at getting a good fit between the panels they are to seal. A thin hood seal is safest, but a thicker one may help a situation where the hood is too flat and need a touch more support in some areas to be level. Some of this fitting was obviously done by Porsche, or panels would not have been numbered. I doubt if they had several hood seals from which to choose, but it helps us now after repairs or panel swaps. Yes, they touch the hood edge to some degree all around and can be a major influence to fit...good or bad.

Think about it...900-series cars evolved to more forgiving foam rubber seals and screw type rubber buffers for lid adjustment.

For Tom; I obviously have not seen all Karmann cars, but I can say with a good deal of certainty that all the disc brake and most drum brake T-6 K-cars had textured undersides of (front) lids and no original T-6 Reutter bodies had that treatment.... at least in my limited experience.

Also, I have noted most original T-6 front lids have a rear 'raised' center area and my guess is that the stamping of the ribs in the cowl actually flattened that somewhat and the lack of level in that area was ignored. I see yours is more level than I am used to seeing, but that looks "right." I do that added step IF there is room laterally for a good gap but if I have to leave the raised area for room at the sides/corners, I say it's "original."

Justin, thanks for everything...especially getting the Bali Blue car picture of Mic's (from Hershey) up in place of a link.

All reading: Please have an enjoyable Memorial Day tomorrow but please remember those veterans who for one reason or another, cannot.

-Bruce

Comment

-

Thank you to all for reporting your gap info! I'm really grateful and appreciate all the photos! What an awesome site.

Bruce thanks for sharing your experience on Karmann hoods texture. Now, I'm thinking that my hood wasn't original due to the texture and lack of factory alignment holes. Also, there were no serial numbers stamped on it, but I understand that the later cars didn't always have numbers stamped there anyway. Either way its not important to me. I just want a hood that fits.

As promised, here is a photo from my very first repair.

This photo shows a few of my first MIG welds. Pigeon Shit!

Even the photo is out of focus... Yikes.

Also, here is a shocking photo with lots of stupid beginner things!

This was back when I actually believed that I could fix one thing at a time and continue to drive the car. Replacing the post was a big job and it was make or break for me. I considered parting out the car after I dug into this. But the repair went fairly well. I put everything back together, spray canned it black, and drove it for another couple of years.

Mistakes:

1) Shouldn't have started with a tough repair

2) Should have removed more of the interior/gauges to prevent damage/fire potential. (especially with MIG)

3) Didn't spend time getting weld gaps perfect.

The repair turned out fine and I'm still confident that its strong enough.

Today, I would have done things a bit different and been more careful.

Thank you to all veterans out there and enjoy your memorial day!

Comment

-

That's quite the repair to take on as a first project! Glad you persevered. MIG welds aren't supposed to look like that?

I'm learning from each new repair I do and starting in areas where my education will not be too visible, before I try for the harder stuff.

Thanks for posting.

JPjjgpierce@yahoo.com

Comment

-

Ha ha, I looked for a while to find the worst one and that was it. It's well covered now with an outer patchOriginally posted by John Pierce" post=19108That's quite the repair to take on as a first project! Glad you persevered. MIG welds aren't supposed to look like that?

JP

The point is everyone starts somewhere and I'm very proud of where I've come. No matter your skill level post here and practice practice practice. That's what's kept me moving forward and not giving up.

I hope someone got a laugh at my expense!

Comment

Comment